Event, News by admin May 15, 2023

Supply Chain Analytics

If you’re in the business world, you’re probably always looking for ways to streamline your supply chain operations. Luckily, supply chain analytics is here to help! By harnessing the power of data and analytics, companies can uncover valuable insights into their supply chain processes, pinpoint areas in need of improvement, and make informed decisions that can boost their bottom line. But like any new technology, there are hurdles to overcome when implementing supply chain analytics. In this article, we’ll delve into the benefits and challenges of this powerful tool, and discuss the architecture that’s necessary to successfully integrate it into your business.

Key Takeaways

- What is Supply Chain Analytics?

- What is the Difference Between Supply Chain Analytics and Supply Chain Management?

- Purpose of Supply Chain Analytics

- What are some examples of Supply Chain Analytics?

- Importance of Supply Chain Analytics

- Five Types of Supply Chain Analytics

- Benefits of Supply Chain Analytics

- Challenges in Implementing Supply Chain Analytics

- Supply Chain Analytics System Architecture

- Role of Big Data

Some examples of SCM analytics include demand planning, sales and operations planning, inventory management, capacity planning, simulation and scenario analysis, optimization, and spend analytics.

SCA is important because it helps businesses improve their performance, reduce costs, and increase profits by using real-time and historical data to make better and faster decisions. It allows companies to gather, assess, and act upon the data generated by their supply chains, making it possible for them to make not only quick adjustments but also long-term strategic changes that will give the business a competitive advantage. As a result, these analytics help companies achieve a lean supply chain, prepare for the future, and better understand risks.

- Descriptive analytics: Descriptive analytics uses data to explain the past and current reality, by examining trends and relationship patterns. Examples of such analyses include the performance of a supply chain or the inventory levels of a warehouse.

- Diagnostic analytics: Diagnostic analytics focuses on understanding the underlying causes of issues or trends in past and current data. It is used to investigate why supply chain shipments have been delayed or sales goals have not been met, by giving insights into past performance that can be used to guide future decisions.

- Predictive analytics: Predictive analytics is a data-driven approach to forecasting and predicting future supply chain events, including demand for a product or potential delays in shipments. By leveraging past data and recognizing patterns, predictive analytics can help businesses make more informed decisions about their operations and optimize supply chain performance.

- Prescriptive analytics: Prescriptive analytics is a type of data-based technology designed to provide recommendations for optimizing decision-making. It uses data to suggest what actions should be taken in order to maximize the efficiency of supply chains, such as selecting suppliers or creating the ideal inventory.

- Cognitive analytics: Cognitive analytics is a powerful tool that relies on artificial intelligence and machine learning to process vast amounts of data. This analysis can generate actionable insights which allow businesses to optimize the performance of their supply chains.

SCA offers a host of benefits that can help businesses improve their operations and reduce costs. Let’s take a look at some of the key advantages of using supply chain analytics:

Let’s take a closer look at some of the key challenges businesses may face when implementing supply chain analytics:

Cost and maintenance of analytical software tools: Implementing these analytics requires the use of specialized software tools, which can be costly to acquire and maintain. This can be a significant barrier for smaller businesses.

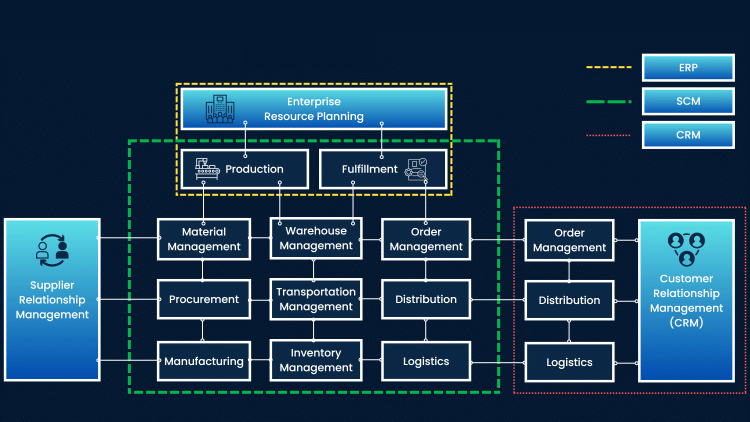

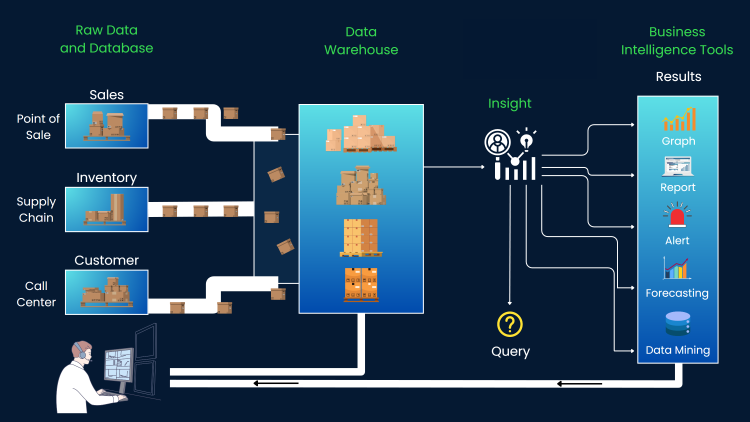

Supply chain analytics is the practice of collecting and analyzing data from every aspect of a company’s supply chain to gain insights that can help optimize operations and profitability. This includes data from sources like enterprise resource planning (ERP) systems, customer relationship management (CRM) systems, suppliers, product manufacturing and testing, quality management processes and shopfloor manufacturing. Additionally, third-party market data such as demographics and marketing information can be utilized to gain further insights. Real-time Business Intelligence (BI) embedded in SCM requires tight integration of manufacturing into analytics, so that information gathered is used to identify design issues, associated costs, and other features throughout the products’ lifecycle as shown in image below:

Supply Chain Analytics – Simplified

Supply Chain Analytics refers to the utilization of data and analytics to improve decision-making around a company’s supply chain operations, performance, and efficiency. This involves examining and enhancing processes like sourcing, manufacturing, logistics, inventory management, and delivery. Through the use of Business Intelligence (BI) tools, businesses can obtain critical insights into their supply chains, enabling them to formulate effective strategies for achieving cost savings and enhancing the customer experience.

Leave a Comment